Core Components and Their Functions

An electrochemical cell is a system that converts chemical energy into electrical energy (galvanic/voltaic cell) or uses electrical energy to drive a non-spontaneous chemical reaction (electrolytic cell). Its design is a meticulous interplay of materials science, thermodynamics, and engineering to achieve desired performance metrics like voltage, current, power, efficiency, and longevity. Every cell, regardless of type or scale, comprises four fundamental components: two electrodes, an electrolyte, and a separator.

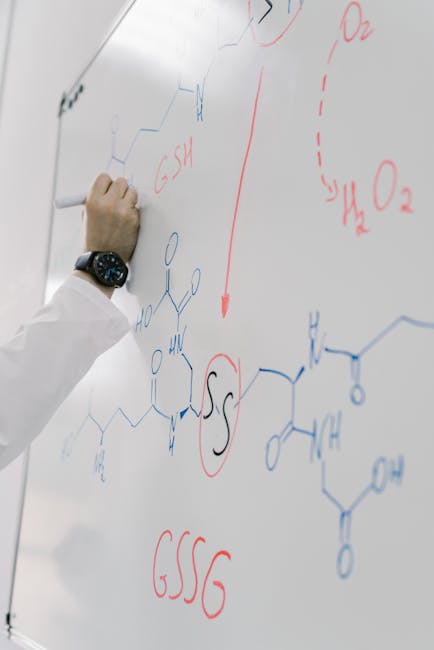

Electrodes: The Surfaces of Reaction

Electrodes are conductive materials that provide the surface for the oxidation and reduction half-reactions. The electrode where oxidation occurs is the anode; the electrode where reduction occurs is the cathode. In a discharging battery (a galvanic cell), the anode is the negative terminal, and the cathode is the positive terminal. This polarity reverses during charging in a rechargeable system.

- Anode Design: The anode material must readily give up electrons. Key considerations include its electrochemical potential (which influences cell voltage), specific capacity (mAh/g), and stability during cycling. Common materials include graphite (for lithium-ion), zinc (for alkaline), and hydrogen-absorbing alloys (for NiMH). Design challenges involve managing volume expansion during ion insertion and preventing the formation of unstable solid-electrolyte interphase (SEI) layers.

- Cathode Design: The cathode material must readily accept electrons and host the species being reduced. Its design focuses on high potential, high capacity, and structural stability throughout the cycling process. Examples include lithium metal oxides (e.g., NMC, LCO for Li-ion), manganese dioxide (for alkaline), and lead dioxide (for lead-acid). Engineers must optimize the material’s porosity to facilitate electrolyte penetration and ionic diffusion.

Electrolyte: The Ionic Conduit

The electrolyte is the medium that allows the movement of ions between the electrodes to balance the internal charge during the electrochemical reaction. It is electronically insulating to prevent internal short circuits. The choice of electrolyte is paramount and depends on the cell chemistry.

- Aqueous Electrolytes: Solutions of acids (e.g., H₂SO₄ in lead-acid), bases (e.g., KOH in NiCd, NiMH), or salts (e.g., ZnCl₂ in zinc-carbon). They offer high ionic conductivity and low cost but are limited by a narrow electrochemical stability window (~1.23 V), restricting cell voltage due to water decomposition.

- Non-Aqueous Electrolytes: Organic solvents (e.g., ethylene carbonate, dimethyl carbonate) with dissolved lithium salts (e.g., LiPF₆) are standard in lithium-ion batteries. They provide a wide voltage window (>4.5 V), enabling high-energy-density cells. Their drawbacks include lower ionic conductivity, higher cost, and flammability.

- Solid-State Electrolytes: A burgeoning field involving ceramic (e.g., LLZO, LATP) or solid polymer electrolytes. They promise enhanced safety by eliminating flammable liquids and enable the use of lithium metal anodes for higher energy density. Design challenges include achieving sufficient ionic conductivity at room temperature and ensuring stable, low-resistance interfaces with the electrodes.

- Ionic Liquids: Salts in a liquid state at room temperature with low volatility and high thermal stability. They are being researched for high-temperature and high-safety applications.

Separator: The Physical Barrier

The separator is a porous, electrically insulating membrane placed between the anode and cathode. Its primary function is to prevent physical contact and direct electrical short circuit between the electrodes while allowing free ionic transport. Its properties are critical for safety and performance.

- Material and Properties: Common materials include polyethylene (PE), polypropylene (PP), or ceramic-coated laminates of both. Key design parameters include:

- Porosity: The volume fraction of voids. Higher porosity lowers ionic resistance but may compromise mechanical strength.

- Pore Size: Must be small enough to prevent electrode dendrites or particles from penetrating and causing a short.

- Wettability: Must be easily wetted by the electrolyte to ensure full pore filling and low impedance.

- Mechanical Strength: Must withstand assembly pressures and dimensional changes during cycling.

- Shutdown Function: Specialty separators are designed to melt and close their pores at a specific temperature, drastically increasing resistance and shutting down the cell in case of overheating.

Key Design Principles and Engineering Considerations

Translating the basic components into a functional cell requires optimizing a complex set of interdependent parameters.

Electrode Engineering: Beyond the Active Material

An electrode is rarely a pure slab of active material. It is a composite structure engineered for maximum performance.

- Electrode Formulation: A typical electrode slurry consists of:

- Active Material: The substance that stores energy via redox reactions (e.g., graphite, NMC).

- Conductive Additive: Carbon black or graphite particles that enhance electronic conductivity throughout the electrode matrix, ensuring all active material particles are connected to the current collector.

- Binder: A polymer (e.g., PVDF, CMC/SBR) that holds the active material and conductive additive together and bonds the coating to the current collector.

- Loading and Coating: The mass of active material per unit area (loading) and the thickness of the electrode coating are crucial. Higher loadings increase energy density but can impede ionic diffusion, leading to power limitations and underutilization of the material, especially at high discharge rates. This trade-off between energy and power density is a central challenge in cell design.

- Current Collectors: Foils (aluminum for the cathode, copper for the anode in Li-ion) that collect and conduct the electrons to the external circuit. They must be highly conductive, corrosion-resistant, and lightweight.

Cell Geometry and Form Factors

The physical arrangement of the components defines the cell’s characteristics and applications.

- Planar (2D) Designs: Used in fundamental research and some solid-state cells. They provide a simple, well-defined geometry for studying reactions but have very low surface area and thus low current capability.

- Cylindrical: Electrodes and separators are wound into a “jellyroll” and housed in a cylindrical metal can (e.g., 18650, 21700 cells). This design is mechanically robust, enables high automation in manufacturing, and is cost-effective. It allows for high volumetric energy density.

- Prismatic: Stacked or wound electrodes enclosed in a rigid, rectangular metal or laminated pouch case. Prismatic cells make more efficient use of space in battery packs (high packing density) than cylindrical cells. The stacked variant often has better power performance due to simpler current paths.

- Pouch (Laminate): Electrode stacks are sealed inside a flexible, multilayer foil pouch. This design offers very high gravimetric and volumetric energy density, lightweight, and flexible form factors. The main drawback is a lower mechanical rigidity, requiring external support within a battery pack to prevent swelling.

Thermal Management

Electrochemical reactions generate heat. Inefficiencies due to internal resistance (Joule heating) and entropic effects contribute to this heat generation. Uncontrolled temperature rise leads to accelerated degradation, reduced efficiency, and thermal runaway—a catastrophic, self-sustaining failure.

- Heat Dissipation: Cell design must incorporate pathways for heat to escape. This involves selecting materials with suitable thermal conductivity, designing cell casings for heat transfer, and integrating thermal management systems (e.g., cooling plates, air flow) at the pack level.

- Operational Temperature Window: Every chemistry has an optimal temperature range. Low temperatures slow down reaction kinetics and increase internal resistance, reducing power and capacity. High temperatures accelerate unwanted side reactions (e.g., SEI growth, electrolyte decomposition) that degrade the cell.

Balancing Energy and Power Density

This is the most fundamental trade-off in cell design.

- Energy-Dense Design: Prioritizes storing as much charge as possible. This is achieved by using thick electrodes with high loadings of high-capacity active materials, minimizing inactive components (current collectors, separators), and using less conductive but higher-energy electrolytes.

- Power-Dense Design: Prioritizes delivering charge quickly. This requires thin electrodes with low loading to shorten ionic diffusion paths, high concentrations of conductive additives to reduce electronic resistance, and high-surface-area current collectors.

The Design and Manufacturing Workflow

Cell design is an iterative process that moves from concept to mass production.

- Materials Selection: Choosing the anode, cathode, electrolyte, and separator chemistry based on the target application (cost, energy, power, safety).

- Electrode Fabrication: Mixing the active material, binder, and conductive additive in a solvent to form a slurry. This slurry is then coated onto a current collector, dried to evaporate the solvent, and calendared (pressed) to achieve the desired porosity and thickness.

- Cell Assembly: Cutting the electrodes to size, stacking or winding them with the separator in between, and placing them into the chosen casing (cylindrical, pouch, prismatic).

- Filling and Sealing: The assembled cell, or “dry cell,” is filled with a precise amount of electrolyte under vacuum and atmospheric conditions to ensure complete wetting. The cell is then hermetically sealed.

- Formation: The first charge and discharge cycles. This is a critical quality control and activation step. It conditions the cell by forming the stable SEI layer on the anode, which passivates the surface and prevents continuous electrolyte decomposition. Formation consumes significant time and energy in manufacturing.

- Aging and Testing: Cells are aged to identify any self-discharge or degradation issues before being graded and sorted based on their tested capacity, impedance, and other performance characteristics. This ensures consistency before they are assembled into battery packs.